Funboats GmbH

Funboats GmbHTel. +49 (0) 67 66 / 96 99 000

Herstellungsprozess der Checkmate Powerboote

No matter the size or model, all Checkmate Marine Performance Boats are built using the same hand-made method as described in this manufacturing process.

This process has been tried and true, tested and proven, with over 40 years of on-the-water experience.

Checkmate Marine doesnt cut corners in the manufacturing of our boats. In fact, we take great pride and care when building each and every Checkmate model to ensure its a long lasting and durable performance boat.

As with most fiberglass boats, we start from the outside and work inward. The two main sections are the deck (top) and hull (bottom).

First, we start with our custom performance hull molds. We take a clean mold and apply several coats of a special release wax to it.

Then, our graphic and paint specialist tape off the required design lines or graphics based on the customers order.

Next, the boat goes into our clean-air paint booth where a gelcoat is meticulously sprayed onto the inside of the mold. This layer of gelcoat is what you see when you look at the boat. Compared to many other boat manufacturers, every Checkmate Marine hull and deck uses a specific application process for the in-gel graphics. An extra thickness of the gel ensures many years of protection for the boat, as well as the ability to hold up to scuffs and scratches.

After the gelcoat is set and cured, the first layer of fiberglass is hand-laid into the mold. This initial step is known as the skin out. The fiberglass adheres to the gelcoat and creates a one-piece bond.

Checkmate uses several layers of fiberglass, cloth, 1708 and mat. Each layer that is created gives strength and durability.

To add additional strength to the Checkmate hull and deck, an extraordinary amount of cure time between each layer is accounted for. This proven technique aids in strength and durability in the finished product.

After several layers of the hand-laid fiberglass have been applied and cured, a layer of Grade A balsa core is precision fitted to the hull and deck. Fiberglass is once again applied over this balsa core insert.

After the shell of the hull and deck are complete, the stringer system is installed. All Checkmate Marine boats use an extra thick stringer system to once again aid in the strength and long-term durability of the boat.

The stringers are then sealed and bonded strongly to the hull using numerous layers of fiberglass and resins.

Once the stringers have finally cured in place, the boat hull is carefully pulled from the mold.

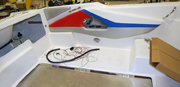

At this stage in the manufacturing process, the deck and hull are still completely separate pieces. They are, however, starting to bear a resemblance to the look of a Checkmate Performance Boat.

Next, we move onward to the custom rigging of the hardware, accessories and new state-of-the-art digital wiring and component system. Again, many of these items are done as a custom process depending on each customers order. All hardware and holes for gauges, wiring, motor, cleats, bow lights, cabin lights, steering, radios and speakers are precisely drilled and/or cut. Then, all parts are mounted into place and attached using only marine grade hardware and fasteners.

It is at this stage that the engine is put in place by Checkmates Certified engine installers.

One of the final stages in the Checkmate Marine manufacturing process is the joining of the deck to the hull. This complex process uses a number of systems to once again ensure a tight, one-piece unbreakable joining of the two sections. The deck and hull are perfectly aligned and tightly fitted together using an extra strong marine grade adhesive, which creates a strong chemical bond. To further strengthen this bond, the two sections are then fastened every six inches to create an additional mechanical bond. Lastly, the seam gets covered with the rub rail, which is fastened into place through the two sections. The rub rail screws add a third level of hull to deck bonding. The rub rail is then fitted with a trim insert to create a clean finish in the final appearance of the boat.

Final assembly takes place. Custom seats are installed, along with cup holders, windshields and countless finish hardware and trim pieces.

Checkmate Marine makes every effort to water test each and every boat leaving our manufacturing plant, weather permitting.

The final stage includes a thorough detailing and cleaning and then a final inspection.

The Checkmate Marine Performance Boat is now ready for delivery. We carefully wrap, package and load the boat on the trailer for its journey to an Authorized Checkmate Dealer.  |

|

|

|